Commercial & Architectual

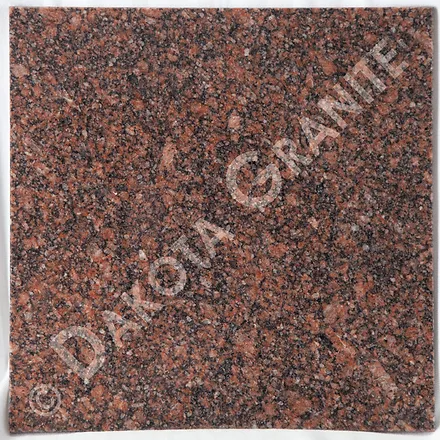

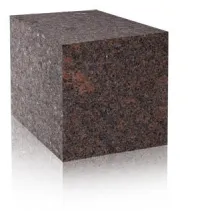

Dakota Granite's Commercial Division, renowned in the international stone industry, serves as a primary supplier of Dakota Mahogany granite blocks to fabricators globally. This distinction stems from Dakota Mahogany's esteemed status as a highly sought-after granite, celebrated not only for its rich and warm hue but also for its durability and intrinsic value. Utilized in a myriad of architectural projects and interior applications worldwide, Dakota Mahogany has cemented its place as a material of choice.

The granite's reputation for excellence has garnered recognition from architects and developers, who appreciate its superior qualities as an ideal construction material. Dakota Mahogany's widespread use in prestigious institutions such as banks, financial centers, hospitals, and corporate buildings is a testament to its prominence. Its composition, featuring feldspar and quartz, imbues a warm, rich tone, offering a comforting and sophisticated aesthetic.

Experience Dakota Granite's hospitality!

We invite you to visit our quarries and headquarters in Grant County, South Dakota. The sales staff and quarry personnel work closely with block inspectors to ensure your needs are met, and block selections have been successful. The personal service, purchasing experience, and shipment of blocks will result in a smooth transaction of goods.

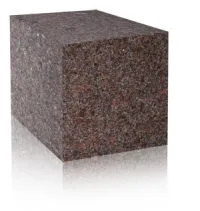

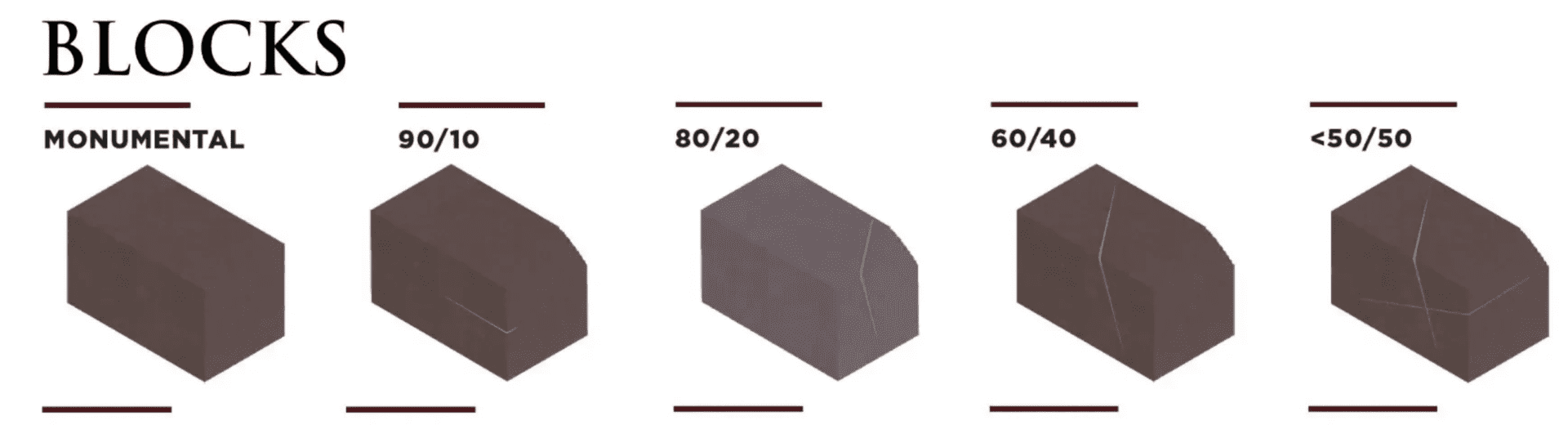

Blocks

Today's quarrying process utilizes wire saws and high-pressure drills. These quarrying techniques have increased quarry yields and minimized stress on the granite blocks themselves. Block inspectors may arrange a block yard visit with our Sales group to select from Dakota Granite's block inventory.

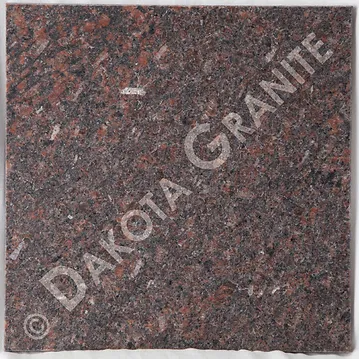

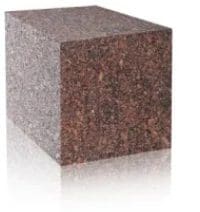

Dakota Mahogany™ Sunset

Dakota Mahogany™ Whetstone

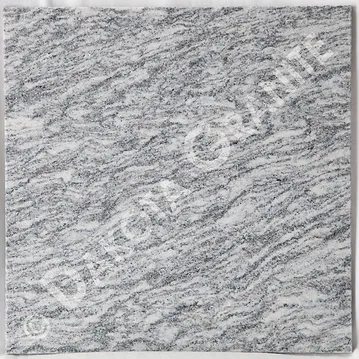

Bellingham

American Bouquet

Superior Black

Construction Limited

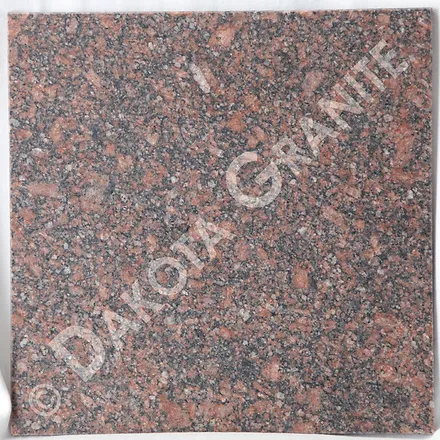

Dakota Mahogany™’s most homogeneous building grade selection is suitable for smaller polished projects where a medium grain with slight to moderate orange variegation is desired.

Construction Standard

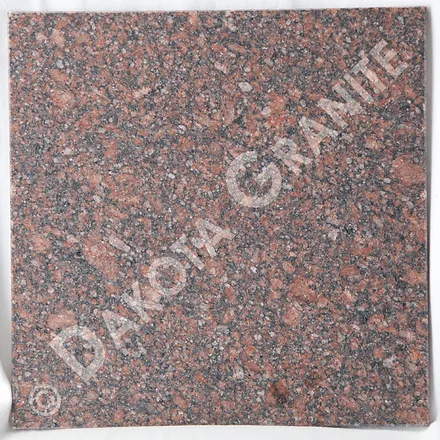

Dakota Mahogany™’s world renown standard, recognized around the world as the benchmark Mahogany color, medium grain with moderate random orange and limited black variegation.

Construction Creative

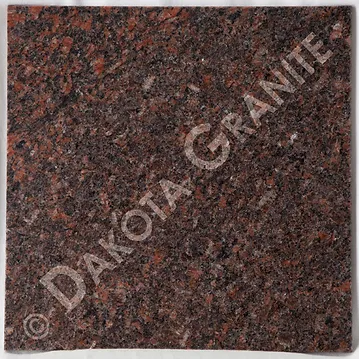

Dakota Mahogany™’s most variegated selection represents nature’s flair for the exquisite with color combinations, grain variations, and patterns that suggest no boundaries.

*FRACTIONS REPRESENT CONDITION OF SLAB

For example a 90/10 slab would be 90% clear and 10% having either a streak, seam or broken corner.

Monumental

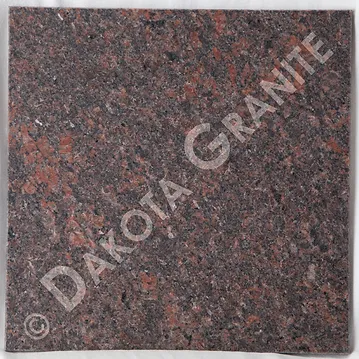

Dakota Mahogany™'s most uniform selection with a limited supply available

Methods of Transportation: Dakota Granite™ is centrally located in the northern tier of the United States. Our headquarters are located 6 miles east of Milbank, South Dakota, near its border with Minnesota. Dakota Granite has been quarrying Dakota Mahogany™ granite since 1925 for use in memorials and commercial projects around the globe.

The original, the only, Dakota Mahogany™ blocks have been shipped to fabrication facilities all across North America and around the world.

METHODS OF TRANSPORTATION OF GRANITE BLOCKS FROM OUR QUARRIES ARE:

1. Flatbed truck

- 46,000 lbs estimated capacity

- single block truck loads - 200 F3 (5.6 m3) maximum

- two or more block truck loads - 183 F3 maximum

2. Container

- 43,500 lbs estimated capacity, 200 F3 (5.6 m3) maximum

- Containers are stuffed at the quarry and transported via truck to the container yard in St. Paul, Minnesota. Blocks are then loaded aboard a train for shipment to the coast to be shipped via vessel.

- Estimated transport time of 6-8 weeks

- Container Stuffing Fee Applicable

3. Railcar

- 200,000 lbs estimated capacity, 850-875 f3 (24 m3) maximum

- Gondolas are railed to eastern rail sites or Norfolk Port. At the port, blocks are placed into containers and loaded onto an ocean vessel. Shipment times vary depending on the booking schedule.

- Ocean-going containers can be loaded up to 60,000 lbs when transported to port by railcar.

The estimated weight of granite blocks can vary because of shape and agreed-upon measurements.

TO ESTIMATE WEIGHT, CALCULATE:

- When sawn to size with packaging for transport: f3 = 190 lbs or m3 = 3.36 tons

- Rough block size: f3= 220lbs or m3 = 3.88 tons

Architectural

Dakota Granite has a long history of working closely with architects, design teams, and specifiers to solve their granite requirements.

Granite is an all-natural product having many uses and applications in the building and construction industries. Granite is the most durable of the natural stone products and one of the most sustainable materials used in the construction field. Because of the numerous quarries around the country, granite often qualifies for LEED points due to the 500-mile or less radius from the quarry to the project.

Virtually 100% wasted or damaged granite pieces can be recycled to be used in other areas of construction or landscaping. Dakota Granite produces products such as thin veneer, full bed ashlar, and various signage products that are manufactured from "scrap" pieces from our monumental division. Granite is abundant in nature, recyclable, low to no maintenance, durable, affordable over the building life cycle, and adds value to your project.

Architectural Product Gallery

Dakota Granite has a long history of working closely with architects, design teams, and specifiers to solve their granite requirements.

Granite is an all natural product having many uses and applications in the building and construction industries. Granite is the most durable of the natural stone products and one of the most sustainable materials used in the construction field. Because of the numerous quarries around the country, granite often qualifies for LEED points due to the 500-mile or less radius from the quarry to the project.

Virtually 100% wasted or damaged granite pieces can be recycled to be used in other areas of construction or landscaping. Dakota Granite produces products such as thin veneer, full bed ashlar, and various signage products that are manufactured from "scrap" pieces from our monumental division. Granite is abundant in nature, recyclable, low to no maintenance, durable, affordable over the building life cycle, and adds value to your project.

Architectural Granite Colors & Finishes

The timeless beauty of natural granite combined with various finishes provides endless creative options to customize any architectural and landscape space. Granite provides durable, low maintenance, and value added features to benefit every investment. Not just any granite... Dakota Granite™.

Polished

Highly reflective mirror finish. Granite color is vivid and distinct. Surface is smooth.

Honed

Slight to non-reflective finish. Granite color is subdued and softened. Surface is smooth.

Sawn

Non-reflective finish. Granite color is muted and toned down. Surface is smooth.

Sandblasted

Non-reflective finish. Granite color is muted and toned down. Surface is rough.

Flamed

Non-reflective finish. Granite color is subdued and softened. Surface is rough.

Rock

Non-reflective finish. Granite color is distinctive. Surface is rugged and irregular.